Category: Tesla silver metallic repair

Tesla Silver Metallic Repair: Unlocking the Potential of Advanced Automotive Technology

Introduction

In the rapidly evolving world of automotive innovation, Tesla has consistently pushed boundaries, shaping the future of transportation with its electric vehicles (EVs) and cutting-edge technologies. Among its numerous achievements is the development and mastery of “Tesla silver metallic repair,” a specialized technique that not only enhances the aesthetics of its vehicles but also underscores the company’s commitment to sustainability and efficiency. This article aims to provide an in-depth exploration of Tesla silver metallic repair, its impact, and its role in shaping the global automotive landscape. We will navigate through various facets, from understanding the core principles to analyzing its economic implications, technological advancements, and future prospects.

Understanding Tesla Silver Metallic Repair: Unveiling the Technique

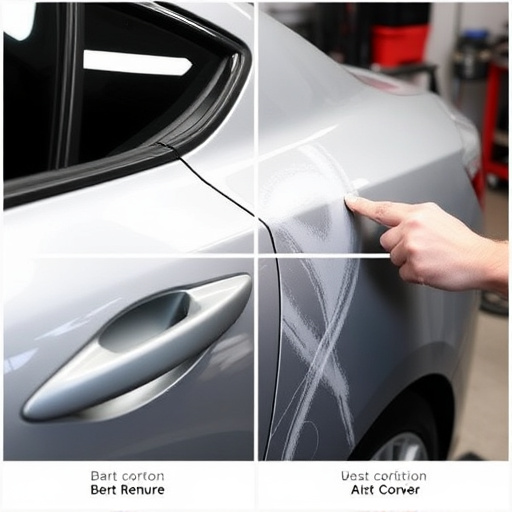

Definition: Tesla silver metallic repair refers to a comprehensive process of restoring and revitalizing the exterior paintwork of Tesla vehicles, specifically focusing on achieving and maintaining a pristine silver metallic finish. This technique goes beyond mere painting, encompassing various specialized procedures to ensure the longevity and aesthetic appeal of the vehicle’s bodywork.

Core Components:

-

Surface Preparation: The repair process commences with meticulous surface preparation, involving thorough cleaning, decontaminating, and ensuring the metal surface is free from any contaminants or existing damage.

-

Sandblasting (Optional): In some cases, a controlled sandblasting technique may be employed to smooth out minor imperfections, creating a clean canvas for the subsequent steps.

-

Priming: An engineered primer is applied to provide an optimal base for the metallic paint, ensuring better adhesion and enhancing corrosion resistance.

-

Metallic Paint Application: This is where the magic happens. Tesla utilizes advanced silver metallic paint formulations, carefully matched to its vehicles’ unique color codes. The paint is applied in multiple layers, each curing at specific temperatures to create a rich, durable finish.

-

Clear Coat Application: A clear protective coat is added to safeguard the metallic paint, enhancing its luster and providing an extra layer of defense against environmental factors.

Historical Context: Tesla’s approach to silver metallic repair has evolved alongside the company’s growth. Initially, standard painting techniques were employed, but as Tesla’s vehicles gained popularity, the need for a specialized, long-lasting solution became evident. Through research and development, Tesla perfected its proprietary paint process, ensuring the iconic silver metallic finish that has become synonymous with its brand.

Significance: This repair method is crucial for several reasons:

-

Aesthetic Appeal: The silver metallic finish is a signature feature of many Tesla models, contributing to their distinctive and modern aesthetic. Maintaining this finish is essential to preserve the vehicle’s resale value and overall attractiveness.

-

Corrosion Protection: The specialized paint system provides advanced corrosion resistance, protecting the vehicle’s body from the elements, which is particularly vital for electric vehicles that may be more susceptible to environmental damage due to their battery packs.

-

Sustainability: Tesla’s focus on sustainability extends to its repair processes. By offering specialized repairs, the company promotes the longevity of its vehicles, reducing the need for frequent replacements and minimizing waste.

Global Impact and Trends

The influence of Tesla silver metallic repair transcends geographical boundaries, with significant implications worldwide:

| Region | Impact and Trends |

|---|---|

| North America | Tesla’s home market has seen a surge in demand for its silver metallic repairs due to the region’s high adoption rate of electric vehicles. Specialized repair centers have emerged, offering advanced training and equipment to cater to this niche. |

| Europe | With stringent environmental regulations, Europe presents a favorable environment for Tesla’s corrosion-resistant paint technologies. The growing popularity of EVs in countries like Germany and the UK has led to increased interest in silver metallic repairs, pushing innovation and standardization. |

| Asia Pacific | This region, particularly China and Japan, is witnessing rapid electrification of transportation. Tesla’s repair techniques are being adopted by local manufacturers to ensure the longevity of their EV batteries and bodywork, contributing to a more sustainable automotive ecosystem. |

| Global Trends | The global trend towards electrification of vehicles has sparked a corresponding demand for specialized repairs. As consumer expectations for vehicle durability and aesthetics rise, Tesla’s advanced metallic repair methods are gaining recognition as industry standards. |

Economic Considerations

Market Dynamics

The market for Tesla silver metallic repair is a specialized segment within the broader automotive aftercare industry. Key factors driving its growth include:

-

Electric Vehicle Adoption: The rapid transition to electric mobility has led to an unprecedented demand for quality repairs, especially as EV batteries and metal bodywork require unique care.

-

Brand Reputation: Tesla’s reputation for innovative technology and premium vehicles attracts a dedicated customer base, many of whom are willing to invest in specialized repairs to maintain their vehicle’s value and appearance.

Investment Patterns

Tesla has invested heavily in research and development to perfect its repair processes, ensuring the long-term viability of its product line. This includes:

-

Training Programs: The company offers extensive training programs for its service centers, ensuring technicians are equipped with the latest knowledge and skills required for silver metallic repairs.

-

Manufacturing Infrastructure: Tesla has established dedicated manufacturing facilities to produce specialized paint and materials, maintaining control over quality and supply chain integrity.

Economic Impact

-

Job Creation: The specialized nature of these repairs has led to the creation of skilled jobs, from paint technicians to repair center owners, contributing to local economies.

-

Resale Value: Well-maintained Tesla vehicles with original equipment metallic finishes can command premium prices in the secondary market, boosting economic returns for owners and impacting the overall vehicle resale industry.

Technological Advancements

Tesla’s commitment to technological innovation is evident in its approach to silver metallic repair:

-

Advanced Paint Formulations: Continuous research has led to the development of more durable and environmentally friendly paint systems, ensuring better performance and reduced emissions during application.

-

Automated Application Systems: Tesla has implemented automated painting robots equipped with precision sensors, enabling consistent and high-quality paint application, reducing human error and improving efficiency.

-

Digital Color Matching: Digital technology allows for precise color matching, ensuring the perfect silver metallic hue every time. This innovation eliminates the need for costly and time-consuming manual adjustments.

-

Corrosion Prevention Technologies: Beyond the paint itself, Tesla has developed specialized protective coatings and sealing agents that enhance corrosion resistance, extending the lifespan of the repair.

Policy and Regulation

The development and adoption of Tesla silver metallic repair are influenced by various policies and regulations:

-

Environmental Standards: Stringent emissions and environmental protection laws in many countries drive the need for more sustainable repair methods, aligning with Tesla’s focus on eco-friendly practices.

-

Safety Regulations: Automotive safety standards require robust testing to ensure that repairs maintain structural integrity and do not compromise vehicle safety features.

-

Intellectual Property Protection: Patents and intellectual property rights protect Tesla’s proprietary paint technologies, encouraging further investment in research and development.

-

Industry Standards: Global automotive industry associations are working towards establishing standardized repair procedures, ensuring consistency and quality across different manufacturers, which benefits consumers and facilitates cross-border trade.

Challenges and Criticisms

Despite its many advantages, Tesla silver metallic repair faces certain challenges:

-

Cost: Specialized repairs can be more expensive than traditional painting, posing a barrier for some customers. However, as demand grows, economies of scale may help reduce costs, making it more accessible.

-

Accessibility: The need for specialized training and equipment may limit the availability of such repairs in certain regions, especially in areas with fewer authorized service centers.

-

Counterfeits: As with any premium service, there is a risk of counterfeit parts and imitations, which can compromise the quality of the repair. Tesla has implemented robust authentication measures to combat this issue.

Proposed Solutions:

-

Education and Awareness: Raising consumer awareness about the benefits of specialized repairs can encourage demand and foster trust in legitimate service providers.

-

Partnerships and Expansion: Collaborating with local businesses and expanding Tesla’s service network can improve accessibility, ensuring more customers have access to these advanced repair services.

-

Technological Advancements: Ongoing technological innovations can help reduce costs while maintaining quality, making silver metallic repairs more accessible and affordable.

Case Studies: Successful Applications

Case Study 1: Tesla Model S Restoration

A premium automotive restoration company in California took on the challenge of restoring a heavily damaged Tesla Model S to its original silver metallic glory. The repair involved:

-

Complete Surface Preparation: Removing deep scratches and dents, along with thorough cleaning and decontaminating.

-

Sandblasting: A controlled sandblasting process was used to smooth out imperfections, preparing the surface for painting.

-

Metallic Paint Application: Utilizing Tesla’s proprietary silver metallic paint, the team applied multiple layers, ensuring a flawless finish that matched the vehicle’s original color perfectly.

-

Clear Coat Protection: A high-quality clear coat was applied to safeguard the metallic paint and enhance its durability.

The restored Model S not only regained its aesthetic appeal but also increased its resale value, demonstrating the tangible benefits of Tesla’s silver metallic repair expertise.

Case Study 2: Sustainable Fleet Management

A large ride-sharing company in Europe sought to reduce its environmental impact by implementing Tesla silver metallic repairs for its growing fleet of electric vehicles. The strategy included:

-

Standardized Repair Procedures: The company adopted Tesla’s recommended repair protocols, ensuring consistency and quality across its vehicle fleet.

-

Training Programs: They invested in training their maintenance staff, enabling them to perform specialized repairs internally, reducing costs and response times.

-

Long-Term Corrosion Protection: By implementing advanced protective coatings, the ride-sharing company significantly reduced the risk of corrosion damage, extending the lifespan of its EVs and lowering maintenance expenses.

Future Prospects: Unlocking New Horizons

The future of Tesla silver metallic repair is filled with promising possibilities:

-

Emerging Technologies: The integration of advanced materials, such as nano-particulate paints and self-healing coatings, could revolutionize the repair process, offering even greater durability and ease of maintenance.

-

Artificial Intelligence (AI): AI-powered quality control systems can ensure precise color matching and consistent paint application, raising the bar for repair standards.

-

Global Expansion: As electric vehicle adoption accelerates worldwide, the demand for specialized repairs will continue to grow, presenting opportunities for Tesla to expand its service network globally.

-

Sustainability Focus: With increasing environmental regulations, Tesla’s commitment to sustainable repair practices will likely become a competitive advantage, attracting eco-conscious consumers and businesses.

Conclusion: Shaping the Future of Automotive Beauty

Tesla silver metallic repair is more than just a painting technique; it represents a fusion of art, science, and sustainability. Through its meticulous approach, Tesla has not only elevated the aesthetic standards of its vehicles but also contributed to the global transition towards sustainable transportation. As the automotive industry continues to evolve, this specialized repair method will remain a cornerstone in maintaining the beauty and value of electric vehicles worldwide.

FAQ Section

Q: How does Tesla’s silver metallic paint differ from regular paint?

Tesla’s silver metallic paint is formulated with advanced pigments and reflective particles, creating a unique metallic finish. It is designed to withstand the rigors of EV ownership, including exposure to harsh weather conditions and road debris. Regular paints, while still effective, may not offer the same level of durability and corrosion resistance.

Q: Can Tesla silver metallic repairs be done at non-Tesla service centers?

While Tesla provides extensive training programs, the intricate nature of these repairs is best performed by authorized service centers with access to Tesla’s proprietary tools, parts, and expertise. However, some non-Tesla centers may offer specialized repair services after completing appropriate training.

Q: How often should I get my Tesla silver metallic vehicle repaired?

The frequency depends on various factors, including driving conditions and environmental exposure. Regular washes and inspections can help maintain the finish. As a general guideline, it’s recommended to have the paintwork evaluated annually or whenever significant changes in weather patterns occur.

Q: Are there any eco-friendly alternatives to Tesla’s metallic paints?

Tesla prioritizes sustainability, and its paint technologies are designed with environmental considerations in mind. While there may be alternative metallic paints on the market, ensuring they meet the same corrosion resistance and durability standards as Tesla’s offerings is essential for long-term performance and ecological benefits.

Q: Can I restore my damaged Tesla’s original silver metallic finish myself?

For best results, it is recommended to seek professional assistance. The process requires specialized skills, equipment, and access to genuine Tesla parts. While DIY kits are available, they may not provide the same level of precision and durability as a professional repair.

Mastering Tesla Silver Metallic Repair and Protection

Tesla silver metallic finish is a protective layer designed to resist scratches, stains, and fading……..

Master Tesla Silver Metallic Repair for Hood, Bumper, and Quarter Panels

Tesla silver metallic repair demands specialized care and advanced techniques for collision damage r…….

Master Tesla Silver Metallic Repair with Digital Tools

Tesla silver metallic repair requires specialized care due to its unique advanced alloys and pigment…….

Mastering Tesla Silver Metallic Repair Techniques for Optimal Results

Tesla Silver Metallic repair involves meticulous inspection and specialized techniques to match the…….

Mastering Tesla Silver Metallic Repair for Hood, Bumper, and Quarter Panels

Tesla silver metallic repair demands expert skill and precision. The process begins with meticulous…….

Master Tesla Silver Metallic Repair for Mirror Finish

Tesla silver metallic repair demands specialized knowledge and techniques due to its multi-layered c…….

Master Tesla Silver Metallic Repair: Chips & Rock Impacts Fix

Master Tesla Silver Metallic Repair: Hood to Quarter Panels

Tesla silver metallic repair demands specialized care, a 5-step process including cleaning, sanding,…….

Mastering Tesla Silver Metallic Repair: Achieve Flawless OEM Clear Coat Match

Tesla silver metallic repair requires specialized coatings and precise matching to OEM clear coat fo…….